The Manufacturing Process

Shoes are one of these merchandise that we put on every day and are a necessity. Although that is a necessity, no person ever appears to ever surprise how the footwear that everybody wears is produced. Well withinside the production manner there are numerous steps, elements of a shoe and in addition to substances. There are many extraordinary substances for footwear. There are positive ones for recreation footwear, get dressed footwear, boots, sandals, and more. Some substances are used to make the shoes comfortable, which allows you to defend yourself from injuries, or to make it appear very exquisite.

Some substances include:

- fabric

- plastic

- rubber

- foams

- metallic

- wood

- leather-based

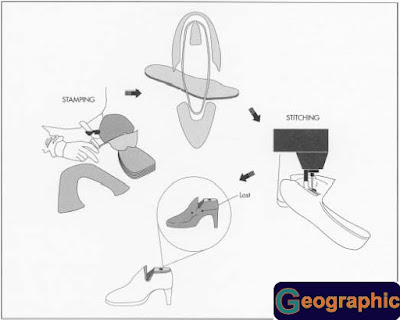

Shoe-making can or is taken into consideration a conventional handicraft profession. There are many elements to a shoe including the sole, insole, outsole, midsole, heel, and vamp or upper. More than two hundred operations are required for making a couple of footwear. However, with the improvement of present-day machines, a couple of footwear may be made in very much less time as every step in its production is commonly executed with the aid of using separate shoes making machines.

There also are many departments with regards to producing the product including click on or slicing branch that offers with the pinnacle a part of the shoe and use leather-based or different substances to reduce out numerous shapes so as to subsequently for the upper. It is the primary manner withinside the making of a couple of footwear. Leather is commonly used on this branch wherein the leather-based is cautiously decided on and the clicker will continue to reduce the formation of the upper, with the aid of using hand, from the excessive first-rate hides. This is a professional and expert activity due to the fact any flaws withinside the leather-based ought to be labored around, and as leather-based may be very pricey any waste ought to additionally be saved to a minimum. After this manner, there may be the remaining or machining branch which offers with stitching all of the additives collectively and as properly including the eyelets wherein, the shoelaces might come from. Next is the lasting and making branch which offers molding the completed uppers right into a form of the foot and in addition to including the plastic shapes that stimulate the foot form. In that branch, they upload all of the soles to it as properly. Then there may be the completing branch which in particular offers trimming heels, sharpening and buffing soles, ensuring that the threshold is waxed, waterproof, stained, and polished, including completing touches after which eventually making it completed.

![Kind-hearted cat [] Squirrel stories](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiYtj5tnC7ZCBPBhB2wGxuGe9eRM915NtHdTiIglqM3A22O2EESkYMcGsXZpoSRdJ1DYeo3YSP9WmIKdq_XbXAI-Vp4QXycaHWhVIf3ltzmwtWtfFJEnwA7Oo0B_7TDnAnZuDuJEWz5Hrhk/w100/cat.png)

![How to new android update; [] Latest Version of Android](https://blogger.googleusercontent.com/img/a/AVvXsEiXrh_H1xc9pMCKPk7uCg3IcgEM-TvXSf_ijOtsicwbJBFUDiuJAR1qUS2IoEWHWZyYbR-EVrZK-fvVYMBPpV_7ObD5bVwK9dRkIFE3o9NpxESdGfPfGF6UOaxPV37AythWUkSspSV8jTwGTKaiZM-YHzcETXut9fEJr6PVqi8LvBxa8a3--KQVuL5OiA=w640)